In the rapidly evolving telecommunications industry, where every tower, antenna, and mounting structure is critical for seamless operation, high-quality data has emerged as a linchpin of success. Accurate engineering data that captures every detail of construction and modification projects minimizes costs, ensures network consistency, and mitigates compliance and safety risks. The stakes are high for tower companies and Mobile Network Operators (MNOs). As the industry grows more complex and interconnected, implementing robust Post-Modification Inspections (PMIs) and Post-Installation Inspections (PIIs) is paramount for ensuring the industry’s highest standards of quality and safety. PMIs and PIIs are also fundamental for powering truly functional digital twins.

This is a deep dive into the importance of quality engineering data validated through PMI and PII inspection processes which is vital for both Tower Cos and MNOs. This best practice is essential to optimizing their long-term cost structures, increasing revenue, and advancing the digitalization of their infrastructure. Utilizing persistent structural engineering data for continuous infrastructure modifications ensures projects are completed with precision, efficiency, and minimal cost. In addition, streamlined engineering and implementation lead to shorter project cycle times and reduced network downtime. Adopting PMI and PII processes is also critical for risk mitigation and helps pave the way for a more secure future in the telecommunications industry. We’ll explore the significance of these inspections, share insights from industry studies, and highlight real-world examples. This paves the way for a more cost-effective and secure future in telecommunications.

The Power of Quality Engineering Data: An Anonymous MNO Case Study

Consider a real-world structural engineering analysis conducted on over 35,000 sites to evaluate the impact of an antenna change. The initial assessment of the antenna changes concluded that a significant structural failure rate would be expected across these sites. The resulting modification recommendations for the MNO would lead to substantial costs and network downtime for them to implement. However, the engineering data captured through a PMI inspection process revealed that relocating the antenna on the mounts would cut the failure rate by 62% – resulting in significant cost savings. This discovery underscores the transformative power of having quality data. When data is collected, managed, and analyzed effectively, it becomes invaluable information that guides smarter decisions, reduces costs, and mitigates risks. This case study is a powerful testament to the impact of quality structural data in our industry.

Post-Installation and Post-Modification Inspections: A Cornerstone of Quality

The importance of Post-Installation Inspections (PIIs) and Post-Modification Inspections (PMIs) cannot be understated. These inspections are critical in ensuring that telecommunications infrastructure is installed and modified according to design specifications. They play a pivotal role in validating what has been installed, how it has been installed, and whether it meets the required design, safety, and performance standards.

The telecommunications industry adheres to the International Building Code (IBC) and uses the ANSI/TIA-222-H standard, establishing that PIIs should be conducted during and after constructing antenna-supporting structures. Similarly, PMIs are crucial for verifying that any modifications to existing structures have been executed correctly. Unfortunately, while these practices are commonly applied to traditional tower structures, they are less frequently applied to antenna mounting structures despite being equally critical.

Per the engineering design, the value in performing a PII or PMI lies in confirming the physical installation of the equipment and ensuring structural integrity is maintained across the entire setup. Most industry failures are not due to design flaws but installation faults, where structures, modifications, or equipment are not correctly installed. PIIs and PMIs close this gap by ensuring every component is installed correctly, reducing the likelihood of costly rework and enhancing overall efficiency. Importantly, these inspections should be viewed as integral parts of the overall project—not as separate cost areas—allowing for the improvement of quality and efficiency while reducing costs.

Consistency Across Networks: A Critical Imperative

Consistency is a fundamental requirement for any successful telecommunications network. Mobile Network Operators (MNOs) and tower companies operate across diverse geographic locations, each with its own unique set of challenges. Without a consistent approach to data capture and inspection, the risk of discrepancies increases, leading to inefficiencies, higher costs, delays with future projects, and potential safety risks.

The role of the Engineer of Record (EOR) in ensuring consistency must be considered. When the EOR is involved in the PII and PMI processes, they link the design and installation phases. By incorporating contractor feedback and addressing any assumptions made during the design phase, the EOR can improve the installation feasibility of telecommunications infrastructure and ensure that future installations are carried out more efficiently.

Moreover, the involvement of the EOR in inspections enhances data management across multiple sites. By standardizing the data collection process, MNOs and tower companies can maintain consistency in their infrastructure, ensuring that every site meets the same high standards. This not only streamlines operations but also simplifies the process of future modifications by eliminating the need for future site mappings, allowing the collected data to serve as a reliable reference point

Risk Mitigation: Protecting Investments and Ensuring Safety

One of the most significant benefits of a robust PII and PMI process is risk mitigation. The telecommunications industry is fraught with risks, from structural failures to compliance issues and safety hazards. Each of these risks can cause significant financial and reputational damage.

A well-executed PII or PMI helps mitigate these risks by comprehensively assessing the installation or modification relative to the exact EOR design requirements, which holds both the contractor and the EOR accountable. By identifying and addressing issues early, MNOs and tower companies can prevent minor problems from escalating into significant failures. For example, missing bolts, misaligned safety climb cables, and incorrect mount installations are all issues that can be detected and rectified through an effective PMI process, thereby avoiding costly and potentially dangerous consequences.

Moreover, compliance with industry standards and regulations is critical to risk management. ANSI/TIA-222 Rev. H and the International Building Code (IBC) set stringent requirements for verifying structural modifications. Ensuring these standards are met through proper inspections protects companies from potential legal liabilities and ensures their infrastructure is safe and reliable.

The Role of PII and PMI in Enhancing Data Quality / Functional Digital Twins

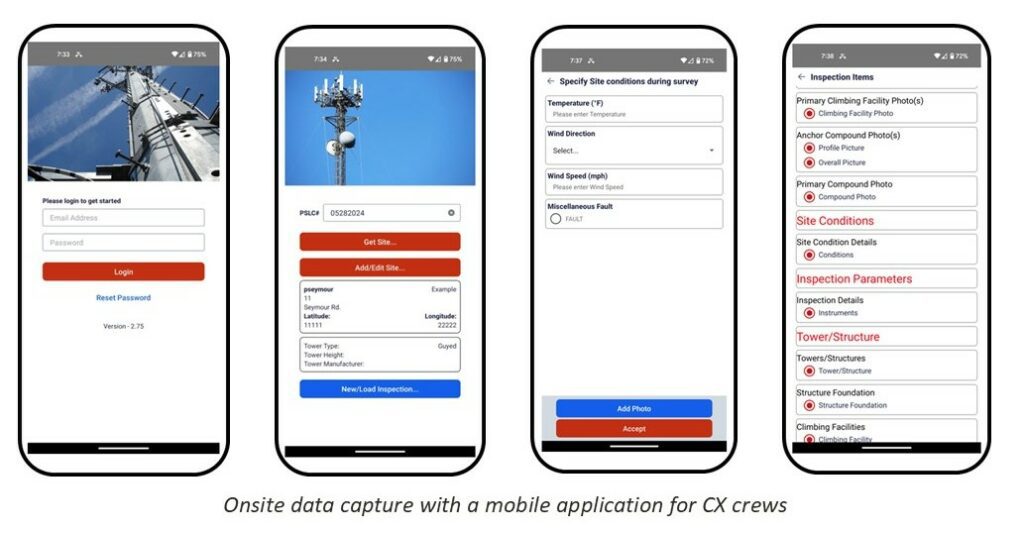

The telecommunications industry is rapidly evolving, and adopting cutting-edge tools and technologies in the PII and PMI processes can significantly improve the quality of data captured. Advanced software integrating PMI and PII data with design models is essential for ensuring that collected data is comprehensive, accurate, and efficient. The EOR plays a crucial role in ensuring that the design intent is fully realized, as closing the design loop eliminates subjectivity in the data. This process also benefits contractors, as the EOR’s accountability enhances their support. When EORs and contractors collaborate, they provide valuable feedback to manufacturers, structure owners, and MNOs.

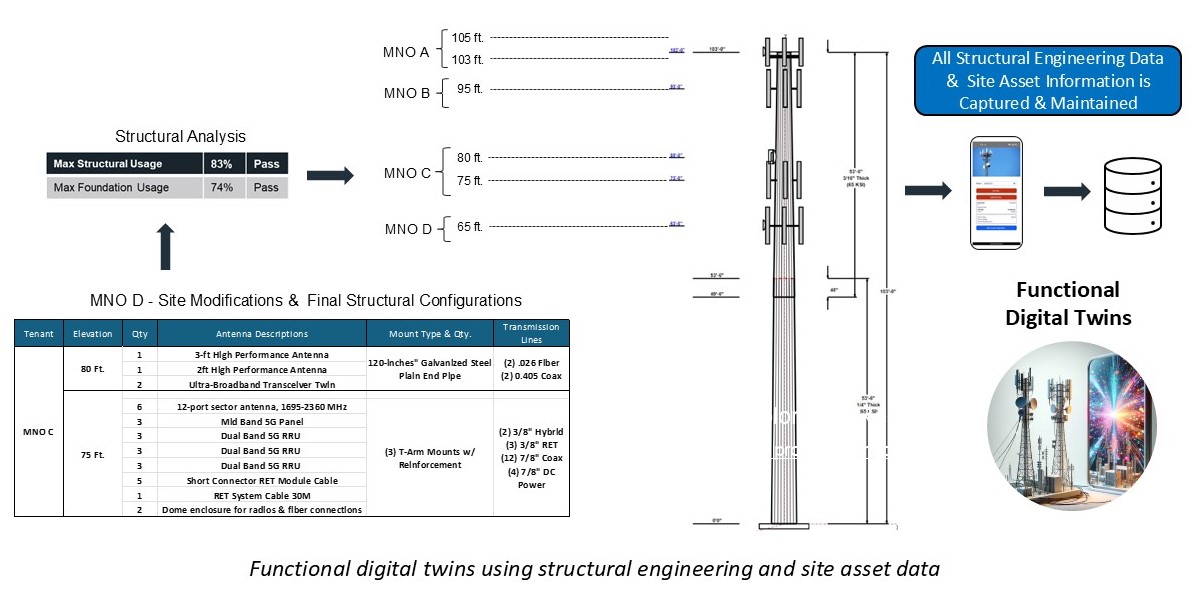

Integrating PII and PMI data with digital twins is one of our industry’s most impactful technological advancements. A functional digital twin is a virtual model of a physical asset, such as a telecommunications tower, built with relevant engineering data that can be relied on and used as actionable information. The true value of a digital twin lies in its accuracy and currency. By maintaining up-to-date and precise digital twins, MNOs and tower companies can monitor the condition of their assets over time to:

- Anticipate potential issues

- Optimize implementation and maintenance schedules

- Implement predictive maintenance programs

- Reduce costs and installation/modification timelines

- Extend the lifetime value (LTV) of their infrastructure and assets

- Leverage quick access to information that unlocks new revenue opportunities

The Financial Impact: Saving Money Through Quality Engineering Data

The financial implications of capturing and leveraging quality engineering data are substantial. Properly conducted PIIs and PMIs reduce the likelihood of costly rework, minimize project delays, and ensure that modifications are completed correctly the first time. This saves money and accelerates the time-to-market for new services and technologies.

Additionally, by maintaining accurate records of inspections and modifications, MNOs and tower companies can better manage their assets and make informed decisions about future investments. Knowing the exact condition of a tower or mount allows companies to plan maintenance and upgrades more effectively, avoiding unnecessary expenses and maximizing the return on investment.

The MNO case study we covered demonstrates how quality engineering data from prior PMI inspections can be utilized to drive quality engineering solutions and lead to significant cost savings. By analyzing the data collected during inspections, companies can make informed decisions that optimize performance and reduce the risk of expensive failures.

Conclusion: The Future of Telecommunications Infrastructure

As the telecommunications industry continues to evolve, the importance of capturing and leveraging quality structural data will only grow. Capturing comprehensive structural data through PIIs and PMIs is the most efficient and cost-effective way to build functional digital twins that Tower/Site owners and MNOs can leverage across their businesses. These processes are not merely regulatory requirements but strategic imperatives for any company that wants to stay ahead in a competitive market. Our commitment to these processes is aligned with industry standards, as highlighted in the recent Planning Advisory Notice¹ published by the Telecommunications Industry Foundation, which emphasizes the necessity of detailed inspections to uphold network safety and reliability.

By ensuring that every installation and modification is thoroughly inspected and accurately documented, MNOs and tower companies can minimize costs, ensure consistency across their networks, and mitigate structural failures and non-compliance risks. Moreover, integrating advanced technologies in the inspection process promises to enhance the quality of data captured, enabling companies to transform raw data into actionable insights that drive smarter decisions and superior outcomes.

Ready to enhance the integrity and efficiency of your telecom infrastructure? Contact us today for a personalized consultation on how our PMI and PII services can transform your operations.